The Science of Purity: How a Color Sorting Machine Works

02-03-2026

Color sorter machines, also known as optical sorters, are a cornerstone of modern industrial processing. They are advanced pieces of industrial machinery that use high-speed optical technology and intelligent algorithms to separate good products from defective, impure, or foreign materials based on color and shape differences.

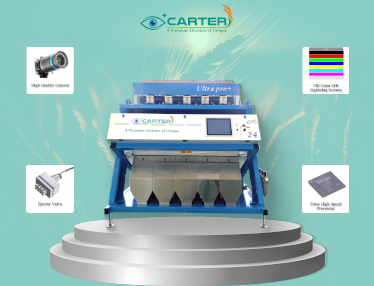

At Carter Unique Group, our technology ensures high sorting accuracy for products like rice, grains, pulses, and nuts.

The 4-Step Precision Sorting Process

The operation of a color sorting machine can be broken down into four critical stages, which blend precision mechanics with high-tech camera technology and Intelligent Algorithms & AI Sorting.

- Feeding and Alignment

- The Material Flow: Raw material (like rice or grains) is fed into the machine's hopper and travels down a chute or on a high-speed conveyor belt.

- Preparation: A vibrating feeder ensures the material is spread out into a single, uniform layer. This prevents overlap, guaranteeing that each grain or particle is individually visible and accessible for inspection.

- Detection and Imaging

- Illumination: The particles pass through an observation zone where they are illuminated by a high-intensity, stable light source (like high-performance LEDs).

- Vision System: As the material passes, high-resolution CCD or CMOS cameras capture real-time, high-definition images. These advanced, multi-spectrum sensors collect detailed color and visual data on every single item.

- Digital Analysis: The captured images are converted into an electronic signal containing detailed color (RGB) data for analysis.

- Intelligent Decision-Making

- Algorithm Processing: An embedded computer system, featuring sophisticated AI sorting and specialized algorithms, processes the collected data instantly.

- Comparison: The system compares the color, size, and shape of each particle against pre-set, user-defined acceptance criteria for the pure product.

- Identification: Any particle that falls outside the acceptable range—a discolored grain, a stone, or a foreign material—is instantly identified and tracked for rejection.

- Ejection and Separation

- Targeted Action: When an unacceptable particle is identified, the system sends an immediate, precise signal to a high-speed rejection mechanism.

- Precision Ejection: High-frequency, pneumatic air nozzles (ejectors) fire a short, powerful burst of compressed air, blowing the rejected particle out of the main stream into a separate collection chamber (the waste outlet).

- Purity Maintained: The good, accepted product continues to fall naturally into the final collection chamber, achieving the industry's highest standards of purity and quality.

This seamless, rapid, and continuous process allows Carter Unique Group's machines to achieve unmatched accuracy, drastically reducing impurities and maximizing the quality of the final product while operating at high capacity.

Unlock the secret to guaranteed product purity! Our color sorter machines use advanced vision systems and AI to analyze every single grain, seed, or pulse. Precision ejection removes defects instantly, ensuring only the highest quality product reaches your customers. Trust Carter Unique Group for innovative, reliable sorting solutions.

Blog Details

Blog Details